1. sing Expected Value Is It Economically Better To Make Or Buy The Component Strategically Thinking Why Might Management Opt For Other Than The Most Economical Choice

Teloxy Engineering has received a one-time contract to design and build 10,000 units of a new product. During the proposal process, management felt that the new product could be designed and manufactured at a low cost. One of the ingredients necessary to build the product was a small component that could be purchased for $60 in the marketplace, including quantity discounts. Accordingly, management budgeted $650,000 for the purchasing and handling of 10,000 components plus scrap.

Elevate Your Writing with Our Free Writing Tools!

Did you know that we provide a free essay and speech generator, plagiarism checker, summarizer, paraphraser, and other writing tools for free?

Access Free Writing ToolsDuring the design stage, your engineering team informs you that the final design will require a somewhat higher-grade component that sells for $72 with quantity discounts. The new price is substantially higher than you had budgeted for. This will create a cost overrun.

You meet with your manufacturing team to see if they can manufacture the component at a cheaper price than buying it from the outside. Your manufacturing team informs you that they can produce a maximum of 10,000 units, just enough to fulfill your contract. The setup cost will be $100,000 and the raw material cost is $40 per component. Since Teloxy has never manufactured this product before, manufacturing expects the following defects:

Percent defective 0 10 20 30 40

Probability of Occurrence 10 20 30 25 15

All defective parts must be removed and repaired at a cost of $120 per part.

Explain Answers to the two questions in 300 words.

1. Using expected value, is it economically better to make or buy the component?

2. Strategically thinking, why might management opt for something other than the most economical

choice?

Image transcription text

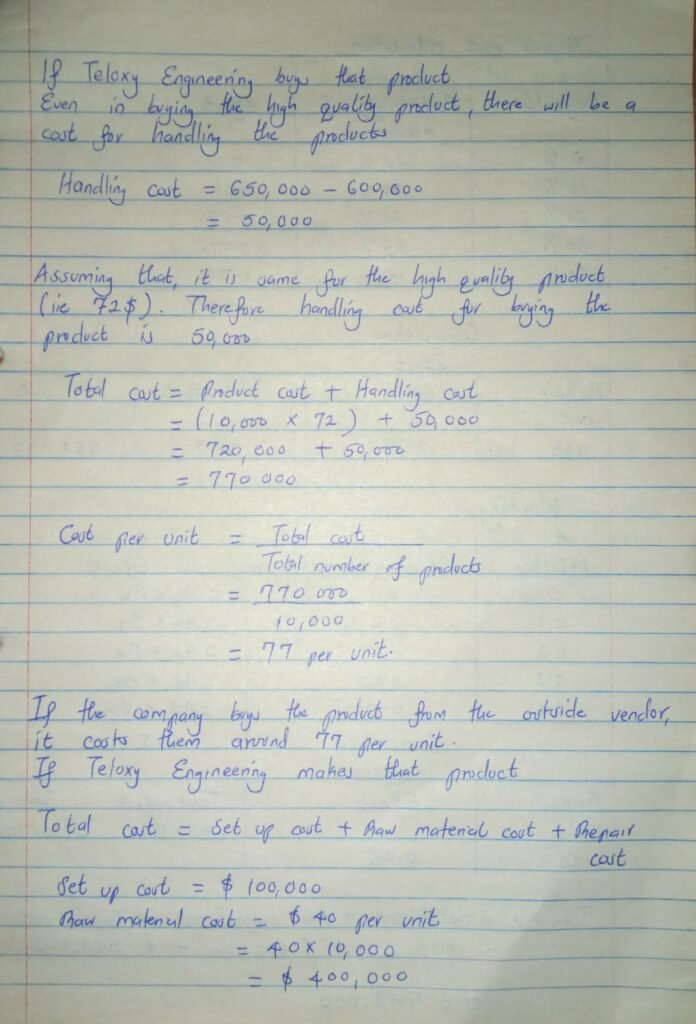

If Teloxy Engineering buys that product Even in buying the high quality product, there will be a cost for handling the -products Handling Cost = 650, 000 – 600,000 = 50,000 Assuming that, it is same for the high quality product ( ive 7 2$ ) . Therefore handling cast -for buying the product is 50, 030 Total cout = Product cost + Handling cost – (10,080 x 172 ) + 50, 000 = 720,000 + 50,000 = 770 000 Cost per unit = Total cost Total number of products = 770 070 10, 00 0 – 7 7 per unit. If the company buys the product from the outside vendor, it costs them around 77 per unit . If Teloxy Engineering makes that -product Total cart = Set up cout + Raw material cout + Thepaid cost Set up cout = $ 100,000 Shaw maternal cout = $ 40 per unit = 40 x 10,0 0 0 = $ 400, 000

Image transcription text

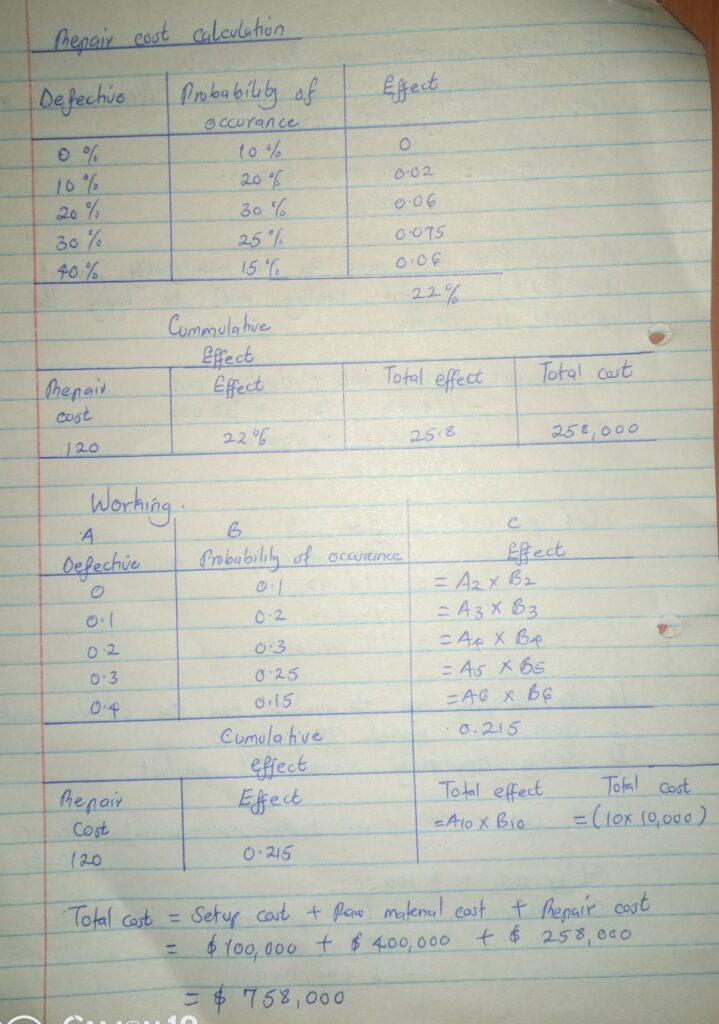

Menair cost calculation Defechue Probability of effect occurance 10 3% O 10 % 20 0.02 20 % 30 % 0.06 30 %% 25%% 0 075 140 %% 15 %% 0:06 22 10 Cummulative effect Shepaid Effect Total effect Total cost cost 120 22 25. 8 258, 000 Working. A C Defective Probability of occurance Effect O = Azx 12 0 . 2 = A3 X B3 0 .2 = AP X BA 10 .3 0.25 = 45 X 6s 0 .4 = AG X BG Cumulative . 0. 215 effect the nair Effect Total effect Total cost Coot = Aiox Bio = (10x 10,000 ) 120 0 .215 Total cost = Setup cost of Raw material cost I Repair cost = $100, 000 + $ 400,000 + $ 258, 000 = $ 758, 000

Image transcription text

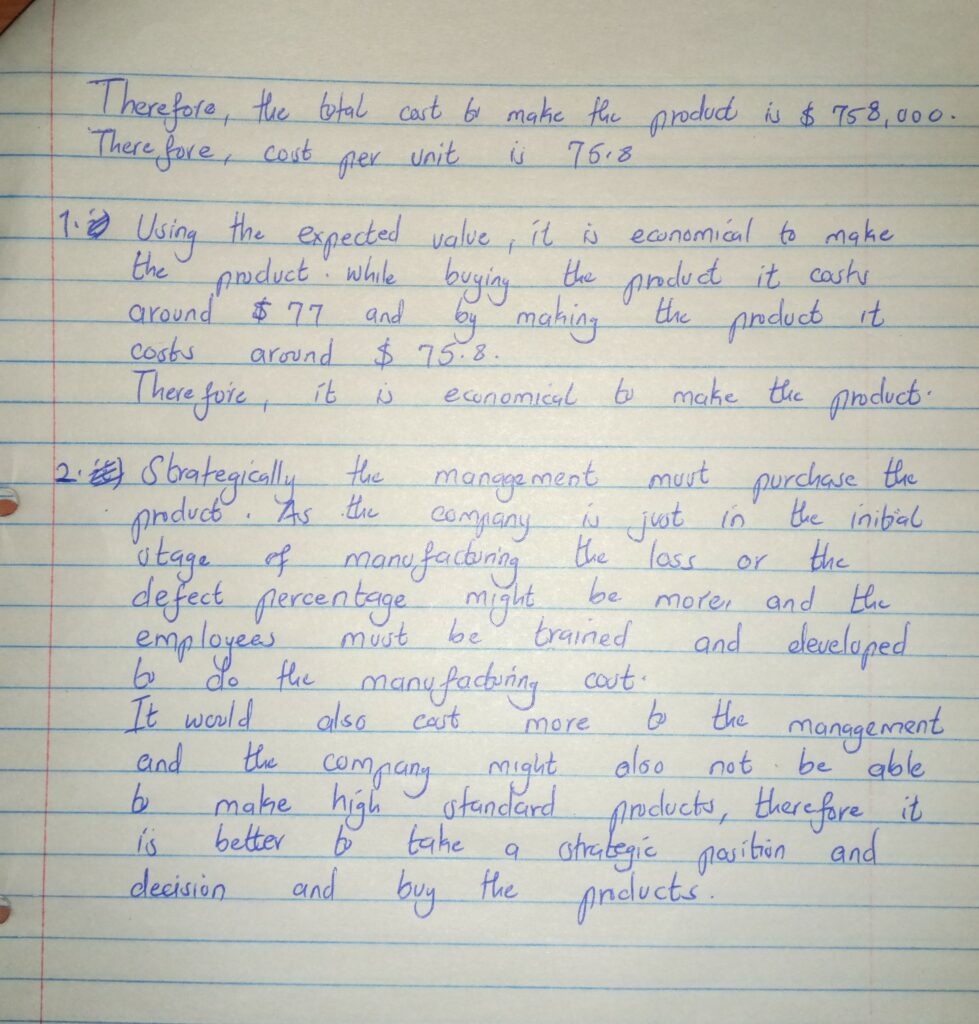

Therefore , the total cast by make the product is $ 758,000 . There fore , cost per unit is 75.8

1. Using expected value, is it economically better to make or buy the component?

Using the expected value, it is economical to make the -product . While buying the product it casts around $ 77 and by making the product it costs around $ 75 .8 . There fore it is economical to make the product

2. Strategically thinking, why might management opt for something other than the most economical

choice?

Strategically the management must -purchase the product . As the company is just in the initial stage of manu facturing the loss or the defect percentage might be mover and the employees must be trained and developed to do the many facbring cout . It would also cast more the management and the company might also not be able make high standard products, therefore it is better take -position and decision and buy the -products.

Special offer! Get 20% discount on your first order. Promo code: SAVE20